Technical Details

Technical Details

PlasTech’s PolyWaste Technology

PlasTech Recycling Pty Ltd has developed an elegant technology coined “PlasTech’s PolyWaste Technology” to cost-effectively transform low-value used plastics into a homogenous molten substrate as feedstock for immediate extrusion and moulding into quality and affordable plastic products.

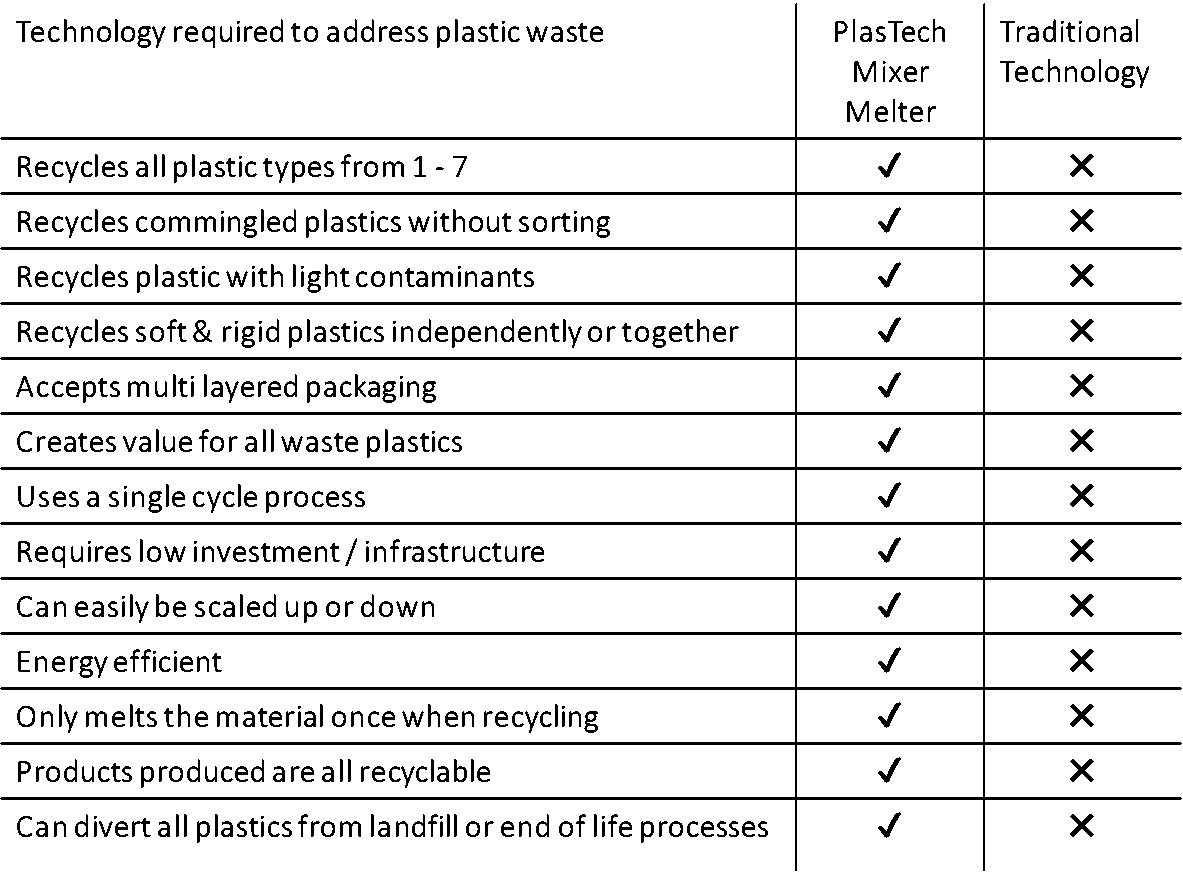

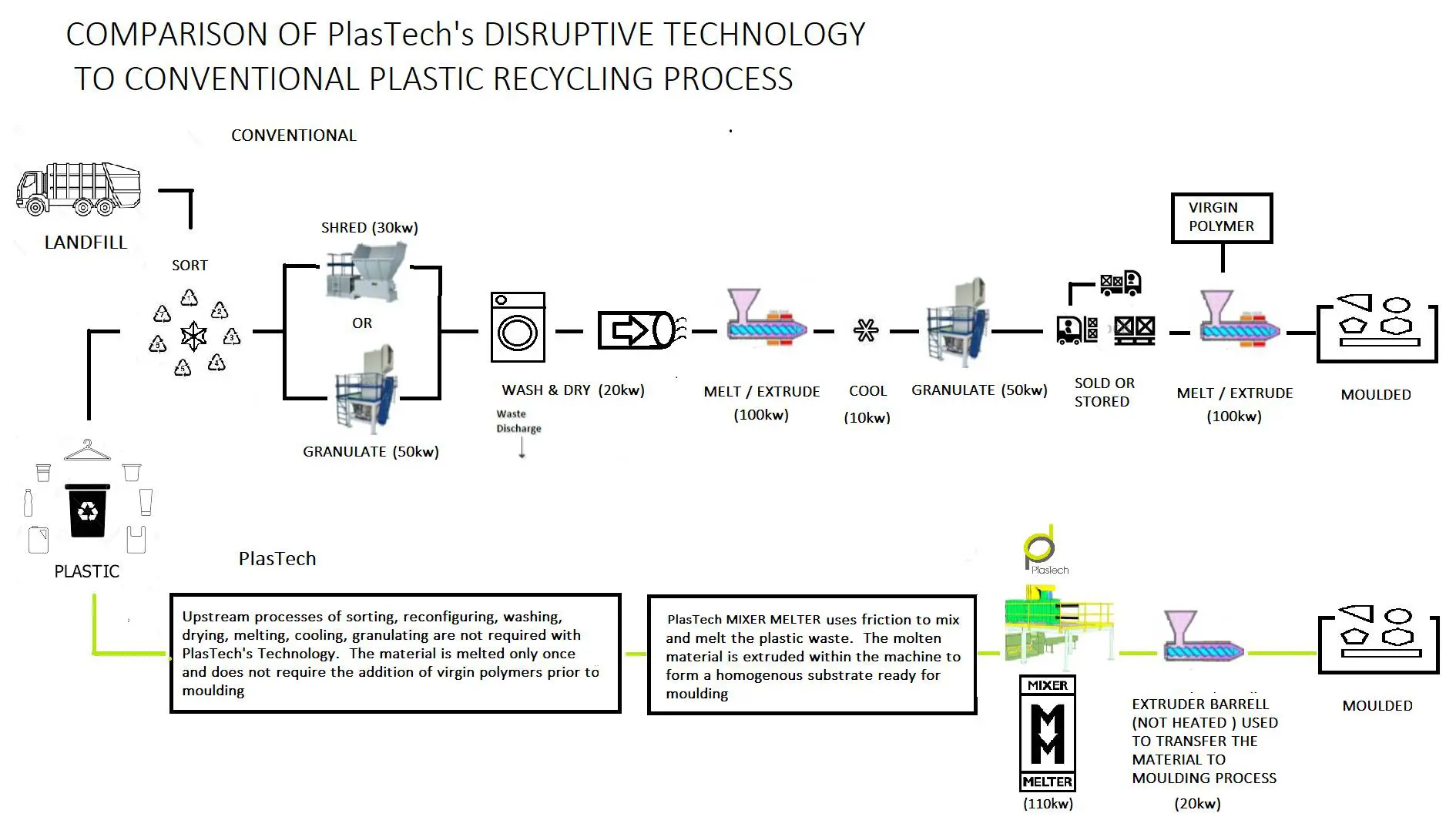

PlasTech’s PolyWaste Technology uses an innovative, unique, and patented process using mechanical (frictional) heat to simultaneously melt and mix used plastics so that infeed mix materials (plastic waste) generally do not require washing, blending, drying, shredding, granulating, or pelletizing beforehand.

This process significantly reduces the handling and processing costs associated with in-feed material preparation and ultimately produces extrusion-ready plastics at an estimated processing cost of $400 per tonne, up to 60% cheaper than conventional recycling methods.

In doing so, all plastic materials, whether rigid or soft, mixed or single polymer and/or lightly contaminated, can now be recycled economically. Traditionally rejected plastic waste now has a value well above disposal to landfill or other end-of-life processes such as energy to waste.

With waste plastic now having a value that can be recognised and easily upcycled into value-added products, both developed and developing economies can benefit from recycling plastic instead of disposing of it.

The opportunity to clean up long-term plastic waste deposits in the environment can also be realised, leading to healthier river systems, oceans, and beaches.

The economic and environmental benefits of upcycling all plastic waste are substantial and further enhanced by the reduced dependence on new plastic production.

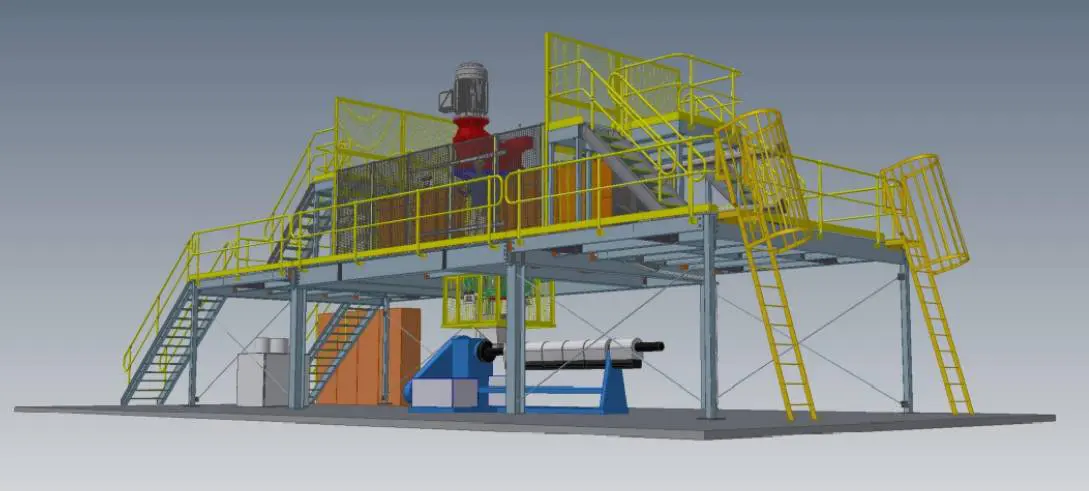

PlasTech Mixer Melter

The PlasTech Mixer Melter utilises a unique and patented process known as PlasTech’s PolyWaste Technology which uses mechanical (frictional) heat to simultaneously melt and mix used plastics into a homogenous molten substrate ready for immediate extrusion and moulding into the quality and affordable plastic products.In doing so, the PlasTech Mixer Melter cost-effectively transforms low-value mixed and lightly contaminated used plastics (soft and rigid) without the need to for upstream sorting, washing, blending, drying, shredding, granulating, or pelletizing of the feedstock.The PlasTech Mixer Melter significantly reduces the handling and processing costs associated with in-feed material preparation and ultimately produces extrusion-ready plastics at an estimated processing cost of $400 per tonne, up to 60% cheaper than conventional recycling methods.The PlasTech Mixer Melter is designed and built in Australia, with future opportunities available to manufacture in most regions of the world by negotiation.Production of PlasTech Mixer Melter Mk1 is due to commence in late 2022, with advance orders already being taken.

Technical Specifications for the PlasTech Mixer Melter Mk1

| Loading Method | Overhead Crane or grab (supplied by customer) |

| Capacity Rating | up to 7000T per annum |

| Bale Size | Up to 1,500mm x 1,300mm x 1,000mm |

| Bale Capacity per chamber | 2 (at 1,000mm x 1,000mm x 1,000mm each) |

| Feed Ports/Chamber | 2 |

| Motor Size | 220kw |

| Drive Type | Electric induction motor with VF drive |

| Transmission | Direct drive via gearbox |

| Power | 3 Phase |

| Power Consumption | |

| Fume Extraction Ports | 2 x 950mm x 150mm (approx.) |

| Fume Extraction System | Site Specific (supplied by customer) |

| Fume Filtration | Site Specific) supplied by customer) |

| Length | 4000mm |

| Width | 2400mm |

| Height | 3000mm |

| Weight | 12 T |